Featured

Branson Heat Staking

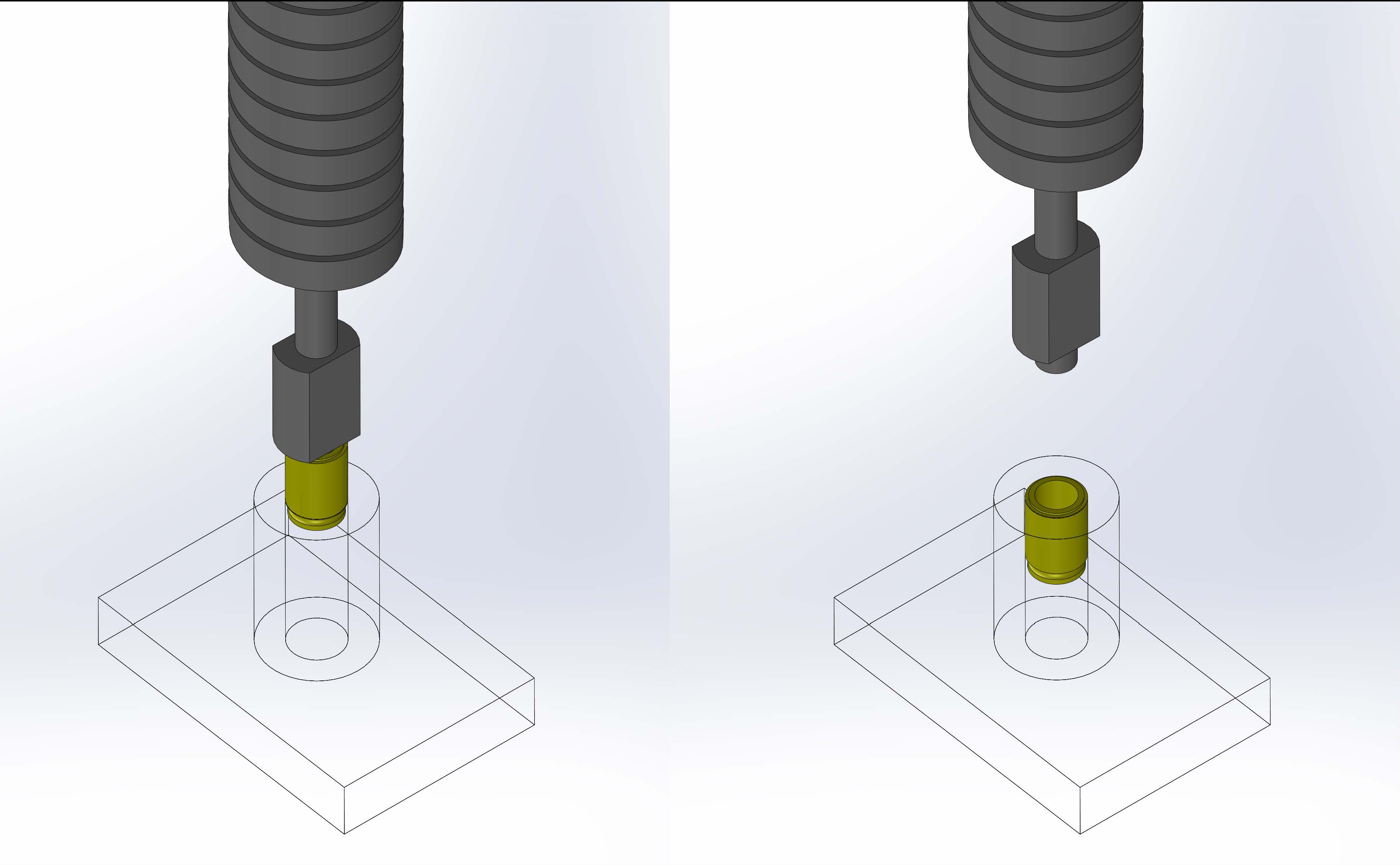

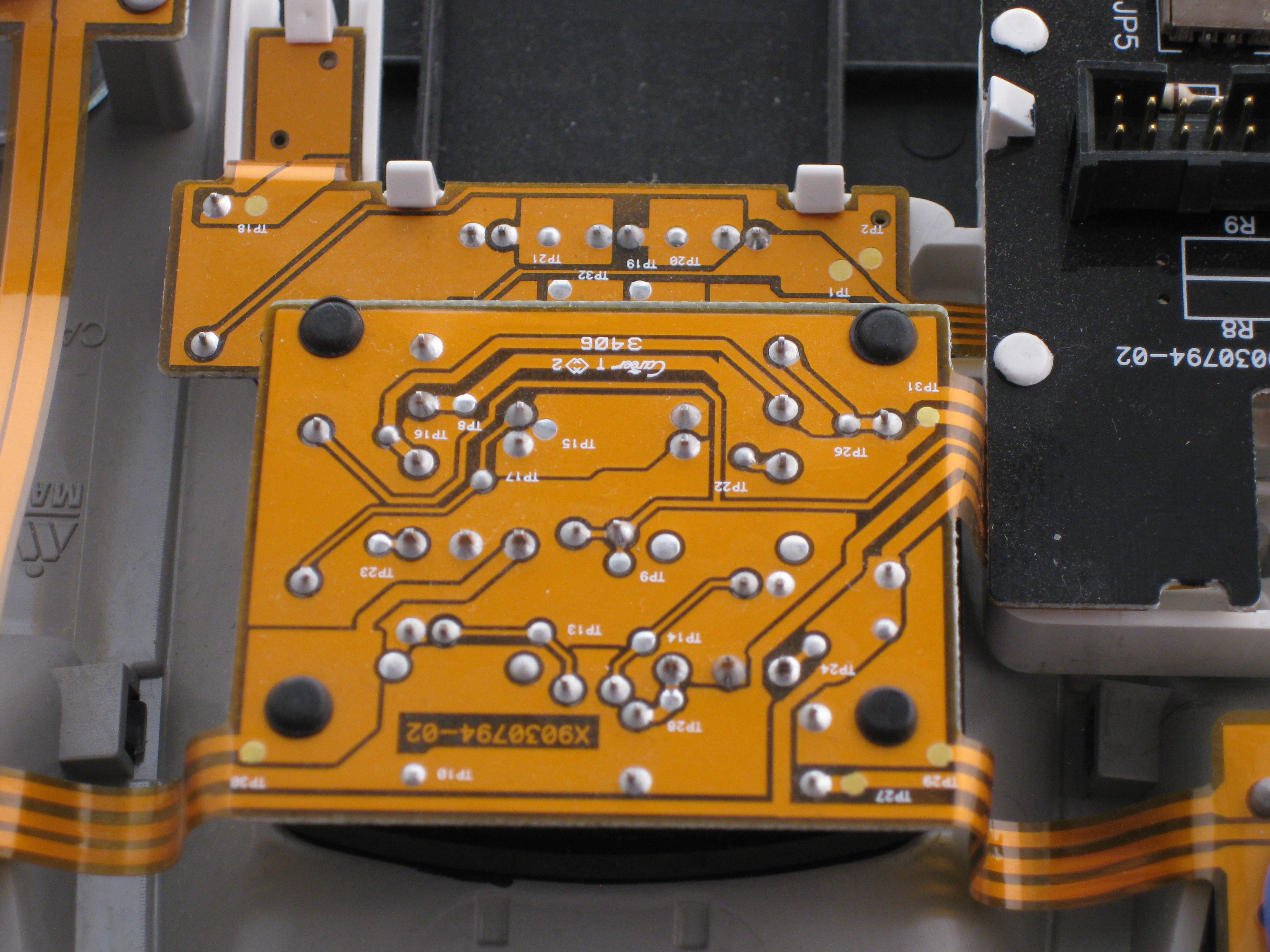

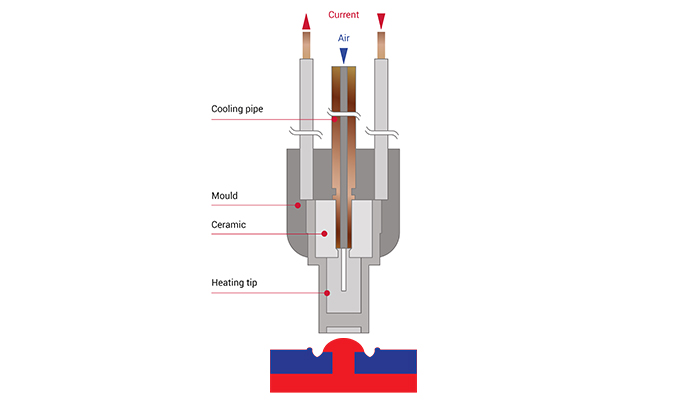

Thermal Staking In thermal staking also referred to asheading or riveting the controlled flow of the molten plastic is used to capture or retain another component joining plastic to plastic metal or any other type of material eg printed circuit boards. Staking eliminates consumables and results in minimal stress in formed plastic.

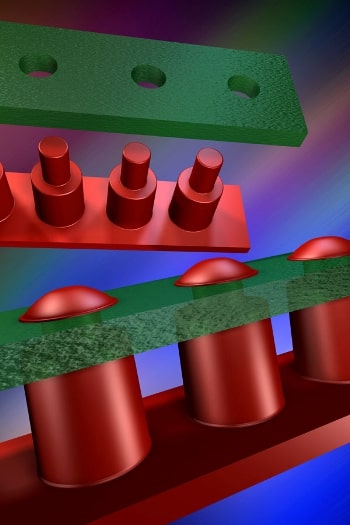

Branson thermal processing supports a design profiles including standard profile low profile dome knurled flush hollow and high-pressure.

Branson heat staking. The Branson GPX platform uses PulseStaker technology to provide instantaneous heating and cooling with adjustable cycle times for optimized low energy heat staking. Our compact precision systems are packed with advanced features options to make your thermal application run more reliably repeatable. Using Branson technology multiple planes can be staked simultaneously.

This includes sophisticated systems with Z-axis servo control for precise rapid and repeatable. Automation Direct 205 PLC. Manual heat staking machines and manual work stations.

The process involves heating and compressing a plastic peg stud or boss so as to soften and deform it in a controlled manner after it. Using a unique pulse staking technology that optimizes the heat staking process the Branson GPX platform produces high-quality. 30 2020 - Emerson has introduced new heat staking technology designed to give manufacturers greater design freedom by enabling them to join more complex delicate and sensitive components to plastic moldings.

Unprecedented control for critical thermal applications. Our manual heat-staking machines and work stations are ideally suitable for thermoplastic joining processes with our heat staking technology which can handle all types of thermoplastic materials including the. Of staking head temperature and downward pressure on strength and processability of both crystalline and amorphous parts.

The process creates no particulates or burn marks and enables more delicate and sensitive parts such as those with embedded electronics to be joined with consistently high-performance finishes. Branson Thermal X Heat Staking Machine. Automation Direct 6 Operator Interface Touch Screen.

To measure and control downward pressure the tool was mounted on a Branson Model 4120 ultrasonic welding. View our Heat Staking Machines. Branson Thermal Processing Systems aredesigned for heat staking thermal insertion swaging degating and date stamping.

The boss is very slightly undersized so that it forms a slip fit. One workpiece has a hole in it while the other has a boss that fits within the hole. The Branson GPX platform has unique heat-staking technology that the supplier Emerson Automation Solutions says provides greater design freedom by.

Staking is the process of connecting two components by creating an interference fit between the two pieces. Heat staking threaded inserts into thermoplastic parts using Soniteks precision arbor style heat staking press. Does Not Produce Metal Flakes or Chips.

The technology is suitable for all heat. TPM 401 Thermal Processor Model 401 Quiet Operations. The process creates no particulates or burn marks and enables more delicate and sensitive parts such as those with embedded electronics to be joined with consistently high-performance finishes.

Temperature Control Monitoring Alarm. Heat staking also known as thermoplastic staking thermostaking thermal staking and hot aircold staking is a method of permanent-joint assembly. OnOff Ramp Soak Post Cooling Shuttle Control.

Emerson heat staking technology enables manufacturers to join complex delicate and sensitive components to plastic moldings. Whether used as a standalone or with other automated technologies to meet aggressive part volume quotas PAS heat staking equipment offers the highest machine control levels in the industry. Heat stakers servo spin welders vibration welders and more.

Trade-ins offered on used equipment when you purchase a new system from PAS. The process creates no particulates or burn marks and enables more delicate and sensitive parts such as those with embedded electronics to be joined with consistently high-performance finishes. Branson GPX platform uses PulseStaker technology to provide instantaneous heating and cooling and adjustable cycle times for low energy heat staking.

Equipment from leading manufacturers such as Branson Dukane Sonics and Materials Herrmann Forward Technology Mecasonic Ultrasonic Seal Thermosonic Sonobond and Rinco. The Branson GPX platform uses PulseStaker technology to provide instantaneous heating and cooling with adjustable cycle times for optimised low energy heat staking. The Branson GPX platform uses PulseStaker technology to provide instantaneous heating and cooling with adjustable cycle times for optimised low-energy heat staking.

Procedure To control staking head temperature a tool was constructed with cal-rod heater and thermocouple near the tip. Sonitek Heatstaking presses are designed with 30 years of expertise.

Https Www Emerson Com Documents Automation Guide Thermal Staking Design Guide Pgs Branson En Us 160174 Pdf

Spot Welding Machine Tpx301 Branson Ultrasonics Thermal Ac Automatic

Spot Welding Machine Tpx301 Branson Ultrasonics Thermal Ac Automatic

Sonitek Heat Staking Ultrasonic Welders Air Pneumatic Presses

Sonitek Heat Staking Ultrasonic Welders Air Pneumatic Presses

Branson Specialized Systems To Enhance Production Emerson Nl

Branson Specialized Systems To Enhance Production Emerson Nl

Emerson Launches Unique Heat Staking Technology To Meet Growing Demand For Complex Plastic Parts Emerson Nl

Emerson Launches Unique Heat Staking Technology To Meet Growing Demand For Complex Plastic Parts Emerson Nl

Branson Tpx301 Thermal Processing System Emerson Us

Branson Tpx301 Thermal Processing System Emerson Us

Comments

Post a Comment